DiMM

Junior Studio 1

Duration: 10 Weeks

Art & Design Expo 2025 Finalist

Design Brief

This project will focus on a small-batch of very well made and customizable mood lighting. The consumer price range will be high end so between $800 and $2000. The current market offers similar lighting options, though many utilize different materials or informal designs, leaving room for innovation. The lamps will provide mood lighting as well as a small amount of ambient light to brighten up a space slightly, this is not meant to be a stand alone lamp to brighten up a room.

Initial Research

It is intended for nightlight environments that use pops of color to brighten up otherwise dark spaces. These lamps could also be used in private game or poker rooms in residential areas. The design will use an LED bulb or light panel that will illuminate the fluorescent acrylic offering mood light. There will also be stained ash accents for the base and to hide electronics. The material choices are not very environmentally friendly unfortunately. The lamps will feature simple plug-in installation and will have a replaceable bulb allowing the longevity to increase. The fluorescent acrylic will need to be dusted regularly as it naturally builds up a static charge.

Potential Retailer

Focus on customizability which my lamp will also have options for, different stains on the wood and multiple colors of acrylic panels

They have around 60,000 items on their website so lots of variety with 2400 pieces that include acrylic so my materials would fit in

They display and sell work from individual artists as well as large firms to create a collection of fine made pieces of furniture, home decor and more

Users, Function, and Context

The users are people that want a unique statement piece for their entertainment area. This could be a bar/ Club or an in home entertainment space.

This light serves to add ambiance to a room as well as bright enough to light up a small space. When used in conjunction with 1-2 other lamps this piece will stand out in a semi dark space.

Market Analysis

Presidents & Analogs

Quality, Technology, Materials, Processes

This lamp will use a standard E26 Light bulb socket with a cylindrical LED bulb

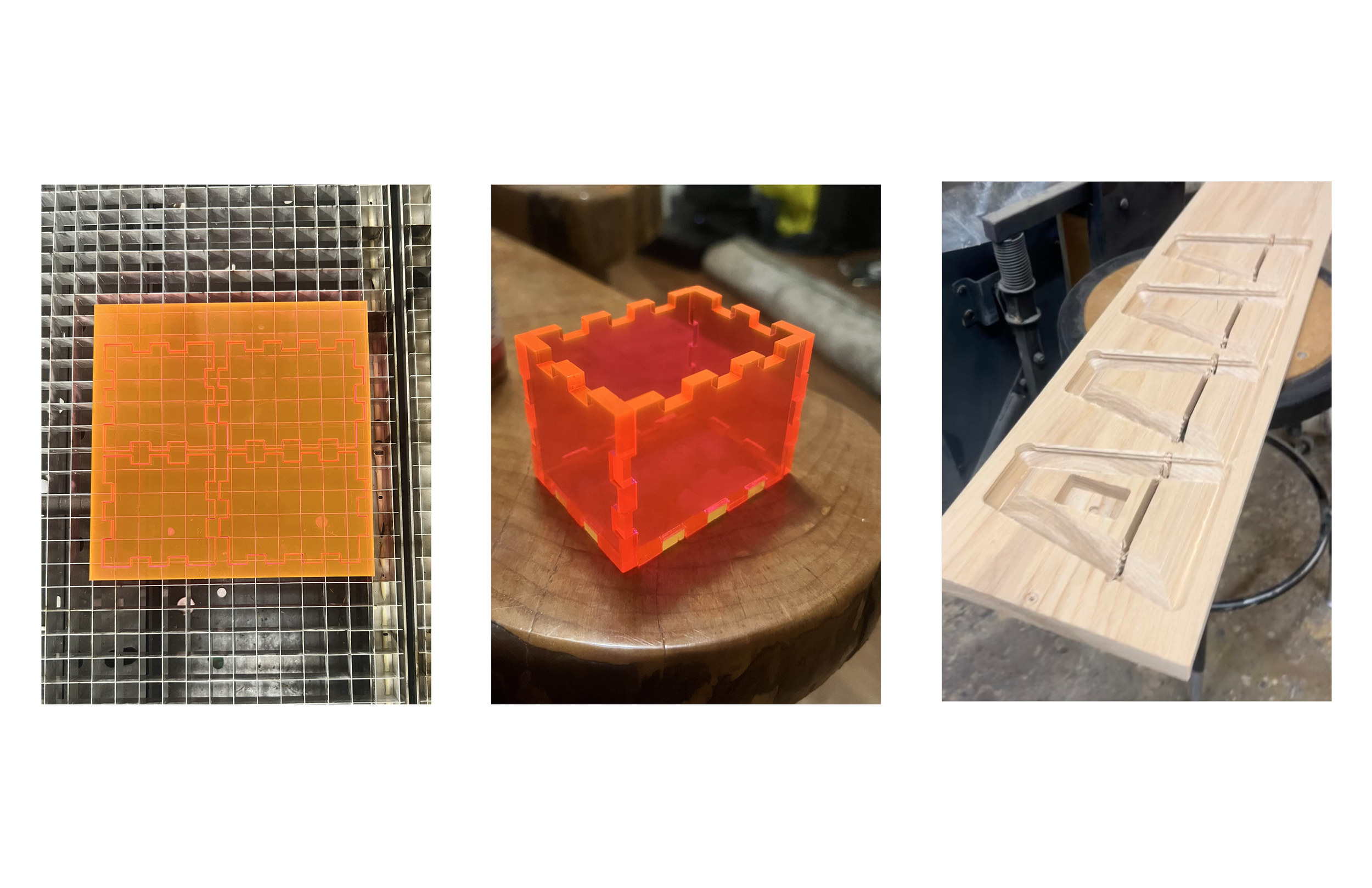

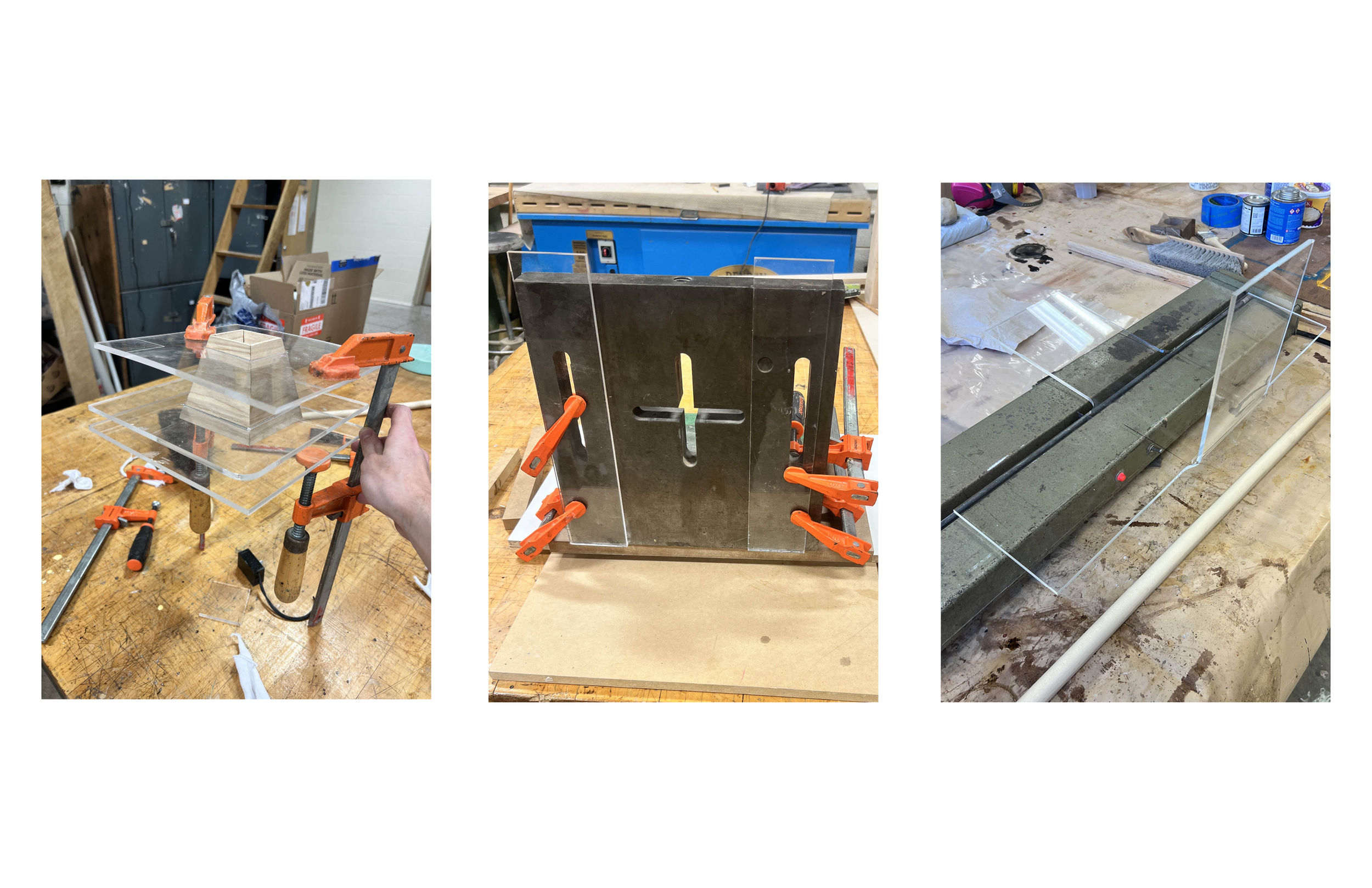

Heat bent acrylic sheets will be used as a lampshade

Environmental Impact

Non sustainably sourced, Is an oil derivative product

Can be recycled back into more acrylic

High material waste when using sheets of it for small objects.

LED’s are highly efficient on power use

Bulb would be on a dimmer system so the LED is also not always on full blast

Thermoforming can be very energy intensive, however I am using thin sheeting, requiring less energy to bend

Initial Sketching

Concept Refinement

Rhino Models

Orthographic and Final Direction

Fabrication Process

Semester Reflection

During the first half of the semester my time management was less than great. I felt behind on my concepts and was struggling to find a good direction to move towards. I used our 2 week break to reset my mental block and when returning for the second half of our semester I began moving quickly. My materials testing was slow but helped me decide what the final form of my light would look like due to limitations in my processes. Once I had my main pieces CNC cut moving to finish it went well. I will have my luminaire finished before the deadline however I will be cutting it close due to wiring components not arriving until 2 days before the due date.

Being a shop tech for the first time this semester has definitely improved my interactions with classmates and I have had lots of opportunities to help other people work on pieces to their lighting or seating. I have also reached out to more upperclassmen this semester to get advice on acrylic bending as well as what finishing processes would best work for my design.

Through this semester I have become very comfortable with our Epilog Laser. I have a good understanding of cutting different materials for myself or classmates as well as some more complicated engravings that classmates needed for templates. Learning how to properly line up cut files to the real material on the bed has been a difficult learning curve however after lots of trial and error I was able to develop an alignment method that is more precise than just looking at the camera output. My acrylic bending tests have also been very valuable information and I now know how to make more organic shapes with molds as well as shapes that require much more precise heating and bending. The shopbot is a great new tool that I feel relatively comfortable operating now. I understand machine setup and running it safely however the file creation process is still something I need to experiment with more. Finally I refined my hand tool skills learning how to use chisels and saws for basic woodworking operations cleaning up the CNC work. In the future I need to remember to sand less to get my miter corners more precise.